Shopping cart

Your Cart is empty

Bedford 51-30002 Pump Rebuild Kit for Graco Pc Series

PriceQuantity

51-30002

MPN:51-30002

Manufacturer:Bedford Precision Parts

Guaranteed safe & secure checkout

Bedford 51-30002 Pump Rebuild Kit for Graco PC Series — AfterMarket by Bedford Precision Parts

This professional bundle is an AfterMarket by Bedford Precision Parts replacement for the OEM Graco PC-Series pump service kit. It’s engineered to restore prime, recover pressure, and stop leaks on popular Graco PC electric airless rigs while keeping maintenance costs predictable.

Where it fits: Designed for Graco 190 PC, 290 PC, and 390 PC sprayers. The kit’s components match OEM dimensions and replace multiple factory part numbers for a true drop-in service solution. According to Bedford, the bundle covers OEM equivalents 18B260 (pump repack), 24W617 (piston rod & valve), and 239914 (prime/bleed valve).

Where it’s used: Ideal for residential, commercial, and industrial projects—latex and acrylic wall paints, primers, block fillers, and protective coatings. A freshly serviced pump stabilizes output to filters, hoses, and paint sprayer guns so crews maintain an even finish at production speeds.

- What’s in the bundle — Three coordinated Bedford service parts:

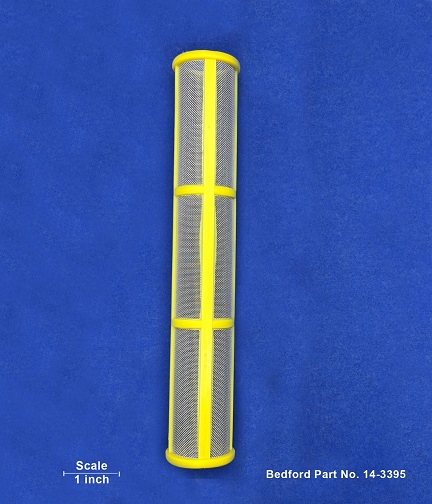

- Pump Repair Kit, 295st/390/395-495st Pro/Ultra 395-495 (Bedford 20-3350) — replaces Graco 18B260.

- Piston Rod & Valve for 190/290/390 PC (Bedford 57-3530) — replaces Graco 24W617.

- Bleed/Prime Valve Kit with solvent-resistant O-ring (Bedford 20-2806) — replaces Graco 239914.

These parts are the exact items listed for the Bedford 51-30002 bundle on the product page.

Why contractors choose this aftermarket set: Bedford’s machining and materials deliver OEM-level sealing and smooth rod travel, helping extend service life between overhauls—all while integrating cleanly with your program of graco paint sprayer parts and broader inventories of graco airless sprayer parts.

Pro install tips: Clean and inspect the piston/rod, seats, and balls; replace scored components. Pre-lube packings as specified, torque fasteners to spec, then flush, prime, and pressure-test at operating pressure before returning the sprayer to production. Keep inline filters clean to protect the rebuilt pump.

Finishing your setup? Explore the full selection at eRepairCenter—your one-stop source for reliable pressure relief valve options, OEM-equivalent speeflo parts, durable wagner paint sprayer parts, hard-to-find binks sprayer repair parts, and more.